Overview

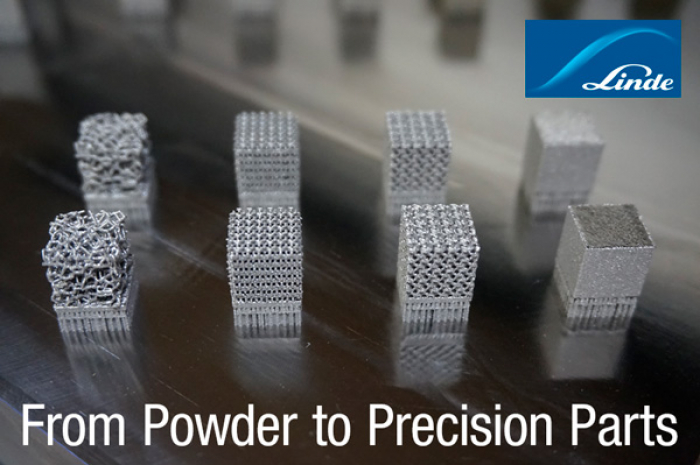

Many laser powder bed fusion (L-PBF) users would welcome an opportunity to increase the reliability and lower the cost per part of this sophisticated AM process. Numerous variables affect the quality of the final part. These include the melting behaviour of the powder, which can also impact the speed at which it is produced and the resulting by-products and fumes. Fumes, for instance, compromise reproducibility by disturbing the laser beam, and by-products can affect parts printed in close proximity as loose powder particles attach to adjacent surfaces, increasing the need for post-processing.

This webinar highlights how the right process gas can enhance process reliability and productivity. We will first share the technical background of the development of our argon-helium gas mixture, namely ADDvance® Laser230. Its benefits will then be compared with argon in terms of ease of qualification, state of surface, porosity and gain in productivity.

Besides, we will present a cost study and the different modes for gas supply.

Finally, we will outline the market trend emphasising that process gas optimisation will be more and more crucial.

Learning Objectives:

- Holistic view of the role of process gas

- Learning how to improve the reliability and productivity of your process

- Understanding the benefits of using ADDvance® Laser230 on a daily basis

Speakers:

Sophie Dubiez-Le Goff

Technology Expert Additive Manufacturing - Linde

Sophie Dubiez-Le Goff, PhD, is a French engineer who joined Linde in 2018. She currently holds the position of Technology Expert in the Additive Manufacturing Team at Linde. She works as Project Manager to develop innovative process gases along the whole AM value chain. Sophie holds an MSc in Material Science from INSA de Lyon and a PhD related to Powder Metallurgy from Ecole des Mines de Paris, France.

Michael Graf

Global Commercialization Manager Additive Manufacturing - Linde

Michael Graf joined Linde in 1998 and has held several positions in R&D and Sales. Since 2019 he has been Global Commercialization Manager Additive Manufacturing and Heat Treatment. Michael is a certified mechanical engineer & holds a B.A. in International Management. He also possesses numerous patents and publications in the field of heat treatment.

Gaël Volpi

Head of Additive Manufacturing - Marle Group

Volpi Gaël is a French engineer and founder of 3D Medlab part of the Marle Group where he is now Head of Additive Manufacturing. After an R&D and process development career in 3D printing for high value markets, he founded 3D Medlab in 2017 which focuses on medical device development and production via additive manufacturing. 3D Medlab was bought by Marle Group in 2021 and he is now responsible for the AM strategy at Marle, a contract manufacturer specialized in large joint implant manufacturing.

Pierre Forêt

Assoc Director R&D Additive Manufacturing - Linde

Pierre Forêt, is a French engineer who joined Linde in 2009. He currently holds the position of Assoc. Director R&D and oversees Linde’s Technology R&D - Additive Manufacturing in Munich, leading a team developing new gas solutions including powder atomization, laser powder-bed fusion and binder jetting. He holds an M.Sc in Material Science.

Sam Davies

Senior Editorial Content Producer - TCT

As part of TCT Magazine's editorial team, Sam has been covering the additive manufacturing industry since 2016, responding to the latest news from behind his desk and garnering deeper insights from business strategists and engineers on trade show floors.

Register Now!

Already registered for this webinar?

Just enter the email address you used to register.

First time here?

Please fill in the registration form below.